Grout, Mirror, Lighting, Tile, Flooring, Faucet

When you watch remodeling shows on TV, you can get the impression that anything’s possible. A shower big enough for a farm animal, an increase in home value that’s higher than some lottery payouts, a window-facing jacuzzi tub with “Best House on the Block” printed on the side in diamonds. All of that is potentially achievable—and probably the reason you want to renovate your bathroom—but you should be aware that a gut renovation is a big, ugly job. The bathroom may take up the smallest footprint, but it’s the most complex room in your home, served by vents, water lines, waste lines, and electricity lines—most of which will try to kill you if you don’t know what you’re doing. (The vents are probably safe.)

If you want to tackle a bathroom reno, you’ve got two options. OK, three, if you’re a professional plumber, or a home flipper with a television show: Put a dumpster on the lawn and have at it. Annars, you can buy your new bathroom by hiring a contractor. Or, you can dramatically improve the appearance and function of your bathroom by cleaning, repainting, or focusing on key projects that require only basic plumbing and electrical skills. Here’s how.

1. Regrout and Recaulk

DIFFICULTY: ●○○○○

Tools and Materials

- Grout saw

- Carbide-tip scoring tool

- Grout Grout float

- Grout and tile sealer

- Plastic brush

- Sponge

- Tub and tile caulk

- Caulk gun

- Utility knife

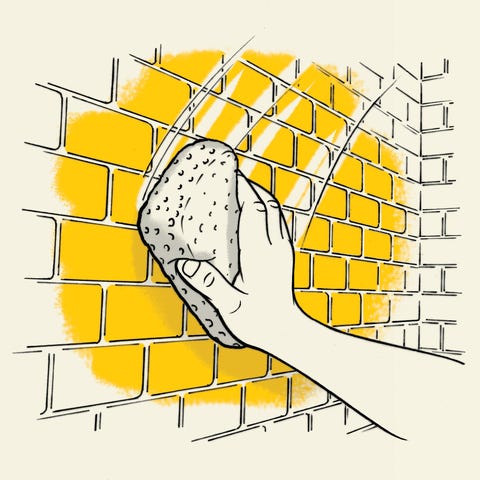

If the grout in your bathroom is discolored but sound, you don’t need to replace it. It just needs a thorough cleaning with a pro-grade tile and grout cleaner, such as the Aqua Mix line by Custom Building Products. If it’s truly foul, the nuclear option would be to scrub dingy tile and grout with a white Scotch-Brite pad, and a mixture of two products from Custom Building Products: Aqua Mix NanoScrub and Aqua Mix Heavy-Duty Tile & Grout Cleaner. If this won’t clean it, nothing will. Eftir hreinsun, seal with Aqua Mix Grout Sealer.

- Painter’s tape Shims

- Mirror adhesive

- Caulk gun

- Mirror clips

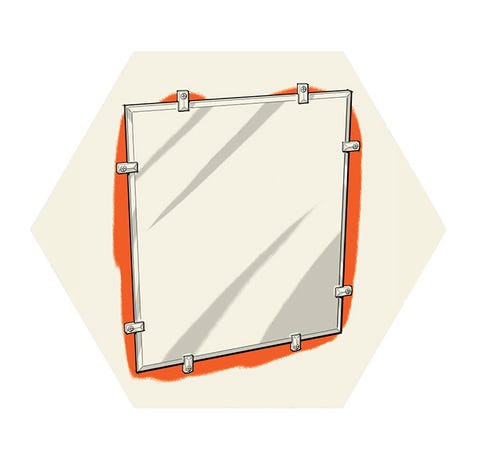

A bathroom mirror is surprisingly easy to remove and replace. Fyrst, determine whether your mirror is held in place with clips or glue. To remove a mirror held with clips, have a helper hold the mirror while you undo the top and side clips. Carefully tilt the mirror forward into the helper’s hands and lift it off the bottom clips. If the mirror feels like it’s still attached to the wall as you try to tip it forward, it might be sticking to the paint or be fastened with adhesive.

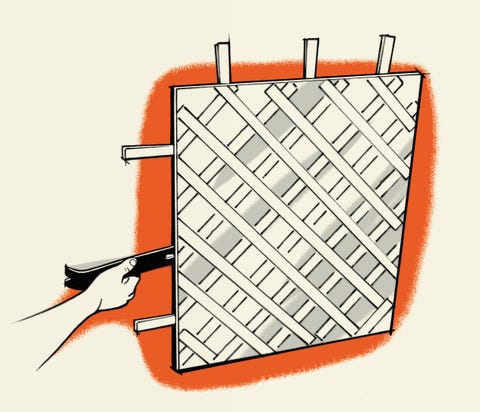

Removing an adhesive-fastened mirror is a tougher job, requiring safety glasses, a long-sleeve shirt, and work gloves. (1) Fyrst, thoroughly tape down and across the mirror with strips of painter’s masking tape so that the whole thing doesn’t break. It’s better to err on the side of more tape than less. Starting at the top center of the mirror, carefully pry it away from the wall using a thin pry bar, then insert a thin shim of wood behind the glass. Work to the left or right sides of the mirror and down, doing the same. You’ll be prying the hardened adhesive off the surface of the wall, lifting the drywall face with it. If the mirror is attached to plaster, the job will be more difficult: Contractors in the plaster days seem to have been real fiends for adhesive, so a mirror installed back then might be stuck pretty tight. The same procedure is used, but be prepared for the worst. With the mirror removed, perform any drywall repair, applying drywall compound with a six-inch drywall knife. Sand patched areas smooth; prime and paint the wall, including behind the mirror.

(2) You can glue your new mirror in place, squeezing lines of adhesive (one specifically rated for mirrors) over the back and making sure to leave two bare inches along the perimeter for the adhesive to spread when you press the mirror against the wall.

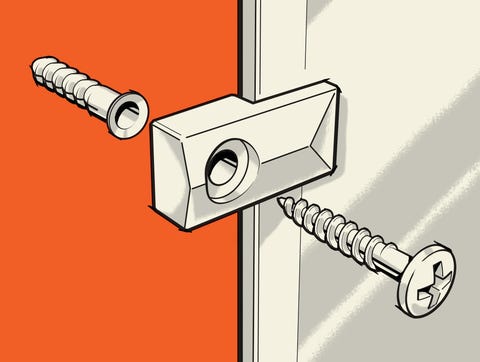

(3) You can also install it using mirror clips and hollow-wall anchors. Or, if you think you’ll change your mind in a few years, choose a framed mirror that you can hang on drywall using hollow-wall anchors and picture-hanging wire.

Back to Projects

Six Products That Will Save Your Butt in a Bathroom Project

3. Replace Dated Wood Trim

DIFFICULTY: ●●●○○

Tool and Materials

- Utility knife Chisel putty knife

- Fishtail pry bar

- Wide, flat knife

- Hammer

- Miter saw

- Wood filler

- Nail sets

- Primer

- Topcoat

- Combination square

Bland, 1970s-era trim really drags down the look of a room. To replace it, you’ll need basic hand tools and a miter saw. You’ll also need a spirit of adventure.

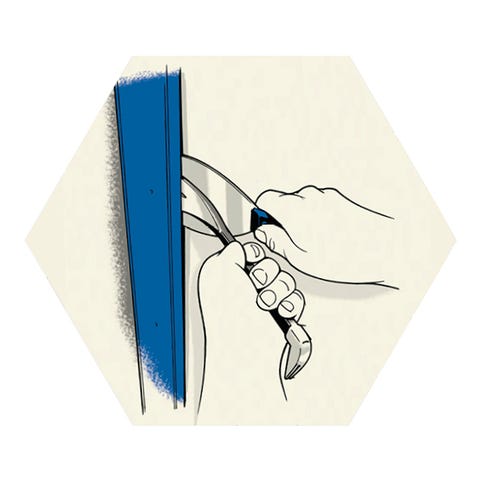

Fyrst, remove the old trim without wrecking everything in sight. Sounds easy, but sometimes it’s not, especially if you just wedge a crowbar in there. Start by slicing the layer of paint or caulk where the trim meets the wall. Then pry the trim away with the thinnest pry bar you can find. I like to begin with a hefty putty knife (called a chisel-type). There is also a bar called a fishtail-type that’s an extremely effective trim-removal tool.

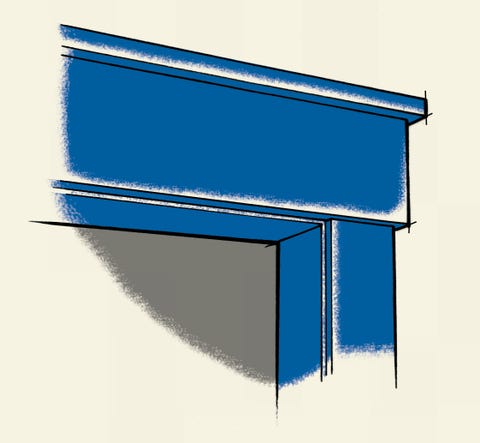

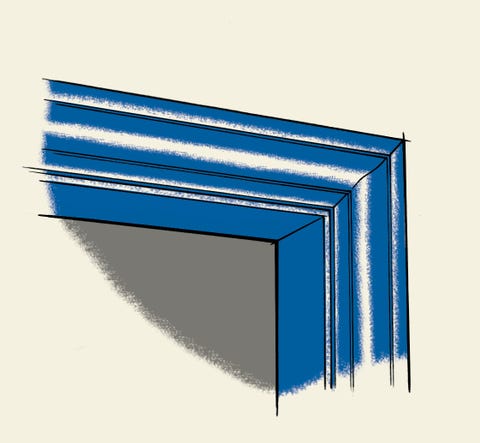

(1) Once you get the trim moving, spread out the prying load by wedging a wide, flat knife between the pry bar and the wall. You may find that the trim pulls off but the nails stay put. That’s okay. You can pull the nails afterward using a locking plier with a block of wood as a fulcrum. The hard part is cutting your new trim. (2) For doors and windows, you can go with a miter-free stacked design or (3) cut a 45-degree miter (diagonal cut) on the end of each piece of trim.

Before cutting any miters, make test cuts on scrap wood and evaluate them with a reliable square. If two 45-degree cuts (or one at 90) don’t make a right angle, adjust the saw per the owner’s manual and reset the pointer at 45 gráður. Also make sure you have a support under the piece of trim as you’re cutting it—even if it’s nothing more than blocks of scrap. Leaving trim hanging off to the left and right as you cut is the mark of the greenest greenhorn. Make your cuts—at 90 degrees or 45—aiming for a tight fit. You may need to lightly nail up the trim before the final nailing to check for fit. That way you can adjust or even remove the trim if you need to recut.

To create a smooth profile once the trim is painted, sink the nails slightly below the surface. If you use a nail gun, it should set the nails as you fire them. To set nails manually, use a trim hammer and a nail set to sink each nail head. (4) Cover each nail with filler; don’t use caulk—it’ll leave an indent. Sand the filler smooth. Apply primer formulated for wood, and a compatible topcoat.

Back to Projects

4. Chuck the Ugly Lighting

DIFFICULTY: ●●●●○ (For minor electrical work)

Tool and Materials

- Sconce Screwdriver

- Non-contact voltage detector

- Side-cutting pliers Wire connectors

- Wire strippers

If you poke around your house and find overcrowded electrical boxes, damaged or burned wires, or aluminum wiring, don’t mess around. Call an electrician. But if you’ve already got a pair of lights flanking your bathroom mirror, and you live in a recently built house or one with wiring that’s been improved by a licensed electrician, upgrading fixtures can be a smooth process.

Fyrst, you’ll need to cut power to the bathroom circuit at the service panel; then try the light switch. No lights? Good. This doesn’t mean that there isn’t a live wire lurking in the box where the fixture is mounted; it just means that the most obvious conductors serving the fixture are no longer energized.

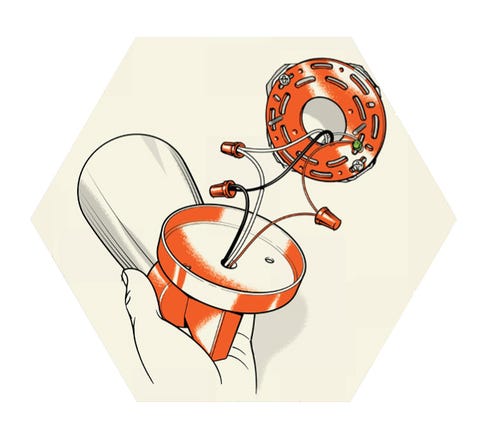

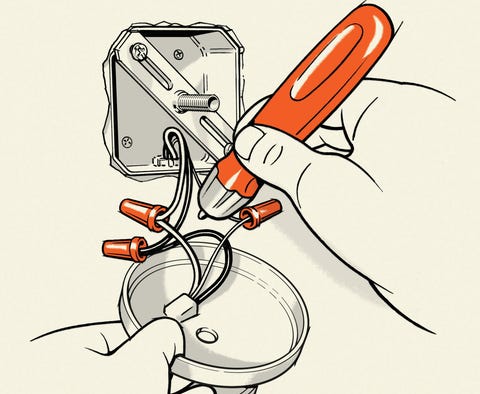

(1) Play it safe by checking wires that you expose by “sniffing” them with a non-contact voltage detector, which senses the electromagnetic field from an energized wire. If you find something amiss, stop and call an electrician.

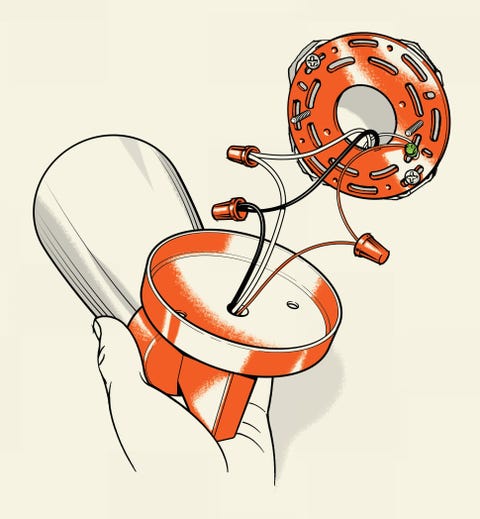

(2) Disassemble the lighting fixture by removing the glass and loosening screws that hold the fixture to the mounting strap or mounting plate. Pull the disconnected fixture forward, gently stretching the wires that connect the fixture to the house wiring. The wires should attach to each other with a twist-on fastener called a wire connector. Untwist these. Set the old fixture aside.

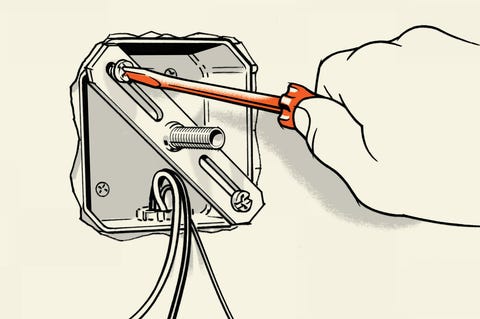

(3) Install the mounting strap for the new fixture to the electrical box and hold the new fixture in position as you connect its wiring to the house wiring: The black house wire goes to the black fixture wire. The white house wire goes to the white fixture wire. Green or bare house wire goes to green or bare fixture wire. You may also see a green ground screw on the plate or strap (see Other Things You Might Find).

(4) Align the stripped end of the fixture wire and the stripped end of a house wire so they are parallel, then twist the wire connector on it in a clockwise motion. Test each splice with a gentle tug on the wires. They must stay firmly put; if not, start from scratch. If you’re nervous about using old-school twist-on wire connectors, try new-school push-in connectors instead. You just push the wire in and you’re done.

Chances are good that the fixture will come with the proper connectors. On the other hand, if these look cheap (and some are), discard them and buy a better-quality connector.

Tuck the connected wires neatly into the electrical box and mount the fixture to its mounting strap or plate; mount its glass components and bulbs. Restart the power, then flip the switch, and you should be rewarded with a pleasing new light.

Other things you might find while doing basic electrical work

If, when your house’s electrical wiring is exposed, you see a green screw sticking out of the mounting strap or plate, you have a ground screw or a bond screw. Electricians have varying views about how to handle these, but you can’t go wrong tightening the green screw down onto a stripped part of the ground circuit you’ve created (green or bare house wire to green or bare fixture wire). 2.There is slim possibility that two of the wires coming from the fixture will be black, rather than an easy, color-coded black and white. In this case, one of the black fixture wires will have a small raised rib on its sheath. Black with a raised rib is the equivalent of the white wire. Attach the ribbed black wire to the white house wire and the smooth black wire to the house black wire.

Back to Projects

5. Upgrade the Faucet

DIFFICULTY: ●●●●○ (for minor plumbing)

Tool and Materials

- Faucet

- Drain assembly

- Pop-up assembly

- Plumber’s putty Thread tape or thread sealant

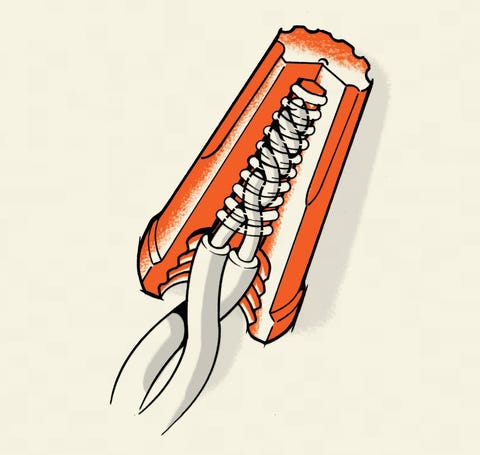

- Tongue-and-groove pliers Screwdriver

- Basin wrench

- Adjustable wrench

- Putty knife

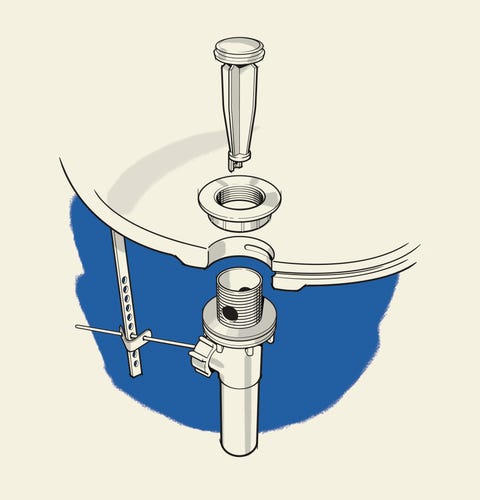

Replacing the faucet and drain assembly can brighten the heck out of a bathroom, and it’s not very difficult, although it does involve minor plumbing. Fyrst, turn off the hot and cold water valves supplying the faucet, and use an adjustable wrench to undo the nut that holds each supply line to its valve. (1) Now, drop out the parts that hold the faucet to the sink.

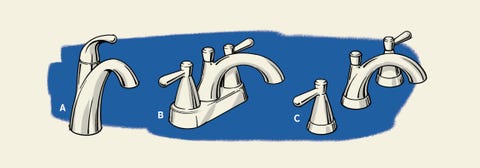

(2) How you’ll do this will depend on whether you have a faucet that is a single handle (a), center set (b), or spread fit (c). Undo the nuts that clamp the faucet body in place or that otherwise prevent the parts from being lifted up and out. Also undo the lift-rod assembly, all the parts that lever the stopper up and down. These connections will be below and behind the sink.

6. Lay Fresh Flooring

DIFFICULTY: ●●●●● (For plumbing, gólfefni, and heavy stuff)

Tool and Materials

- Flooring

- Pull bar Wet/dry vacuum

- Mallet Tapping block

- Tape measure

- Utility knife

- Combination square

- Straightedge

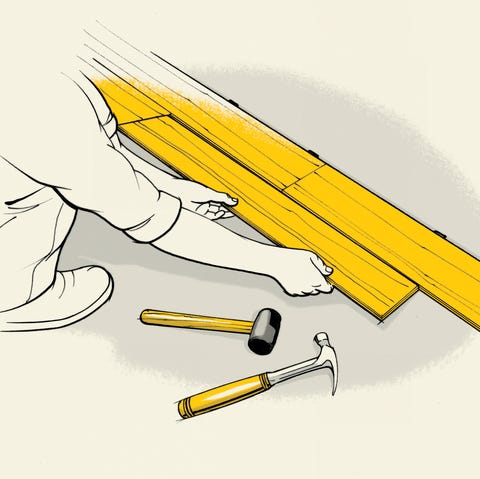

If your bathroom tile is sound, frankly, you’re better off cleaning it, sealing it, and leaving it alone. Tearing out porcelain tile and replacing it is a huge deal. If the bathroom has an ugly vinyl floor, however, a good fix is to install a form of waterproof floor known as solid core LVL (luxury vinyl tile). Solid core LVL is a form of plank flooring that looks very similar to the laminate floor types that have become popular in the last 20 ár. The biggest difference: The base of each plank is water-resistant, and the center is made of pulverized limestone and plastic resins. The faces can be printed to look like stone or wood.

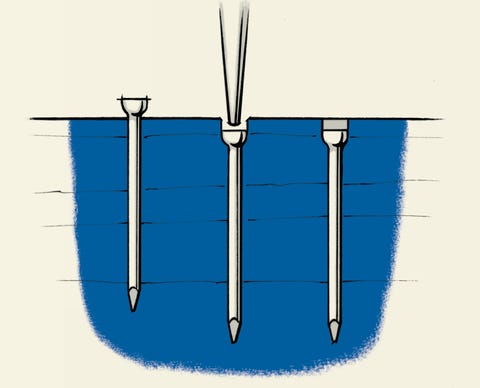

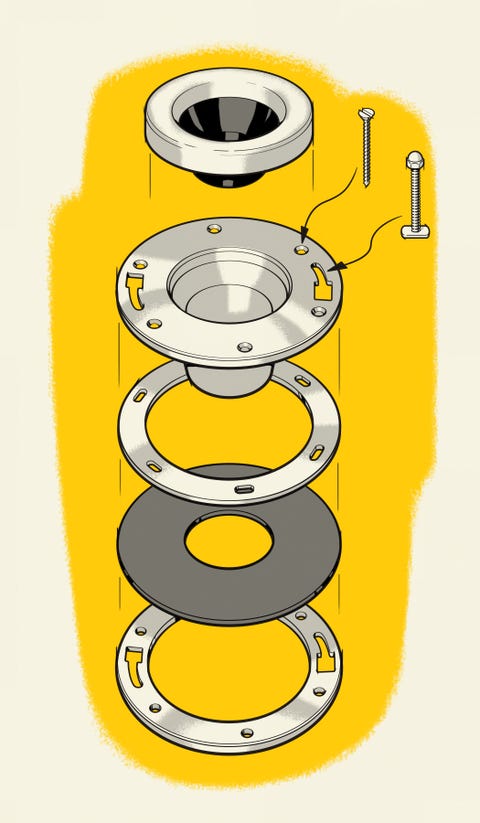

Some solid core LVL planks can be installed directly over existing flooring. Others require that you first roll out a protective sheet. The process is pretty simple. (1) The long axis of the planks align with the long axis of the room. You start on one side and lay down the flooring parallel to the wall, clicking each piece onto its neighbor as you go. The manufacturer may advise you to use a thin bead of specialized glue at each plank, og (2) silicone caulk in the gap where the flooring meets the wall, trim, vanity, tub, or shower curb. If there is a cold water supply tube through the floor that supplies the toilet, you may need to very carefully caulk the cavity below the escutcheon. The most difficult step in the entire job likely will be removing the toilet before installing anything, so the flooring goes under it and not around it. Some manufacturers say it’s okay to cut the flooring around the toilet, but you don’t want that. If condensation runs down the face of the toilet, or there is a plumbing leak, water could get past the sealant at the base of the toilet and seep under the flooring. You might not find out until you have a disaster on your hands. To remove the toilet, turn off its water supply and undo the connection for the cold-water line.

VIGA blöndunartæki framleiðandi

VIGA blöndunartæki framleiðandi